Every year, the world produces staggering 92 million tonnes of clothing waste. We prioritise utilising digital tools and keeping up with sustainable advancements in the fashion industry to leave a positive impact on the environment.

Over the past decades, the textile industry has made significant strides in sustainability, including reducing water and energy consumption, minimising landfill waste, and limiting the use of harmful chemicals. The industry is now expanding its scope from solely integrating sustainable practices to adopting strategies that enhance the sustainability of a product’s entire life cycle. Throughout a textile product’s life cycle, there are many opportunities to reduce its negative environmental side-effects, such as the amount of carbon dioxide emitted in its production, waste disposed in bodies of water and landfills, and wasteful by-products in general. Given that the fashion industry generates approximately 92 million tonnes of landfill waste annually, it is imperative for all stakeholders to adopt more digital and eco-friendly practices.

To further advance our digitally enabled sustainability initiatives, featuring LIMITED has developed four streams to minimise our contribution to landfill waste: material virtualisation, digital pattern development, 3D style creation, and product sales and marketing.

Material Virtualisation

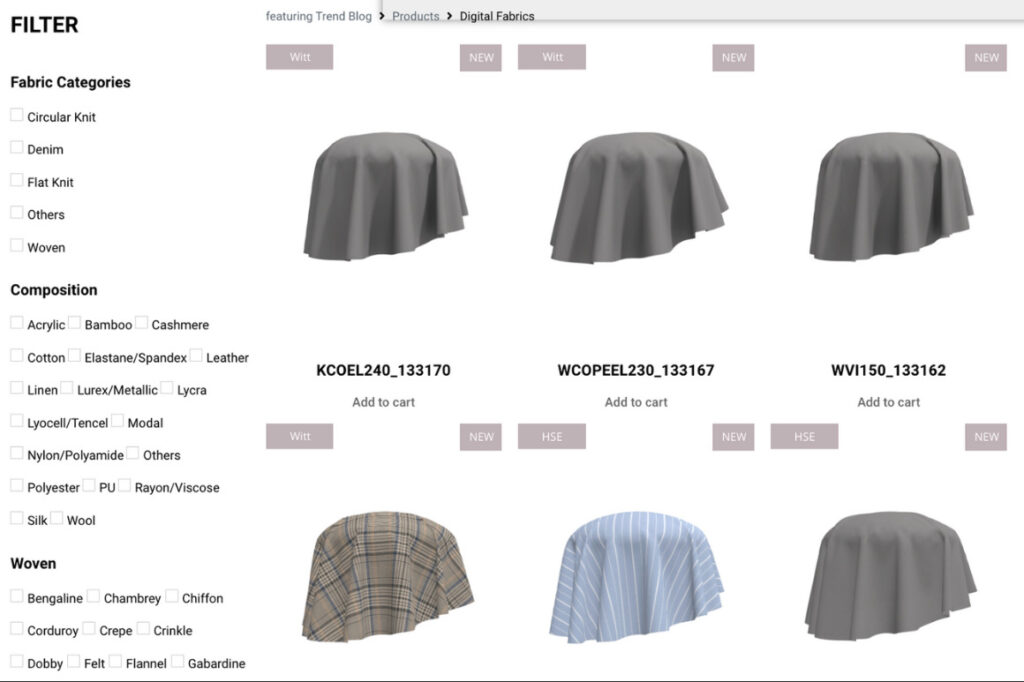

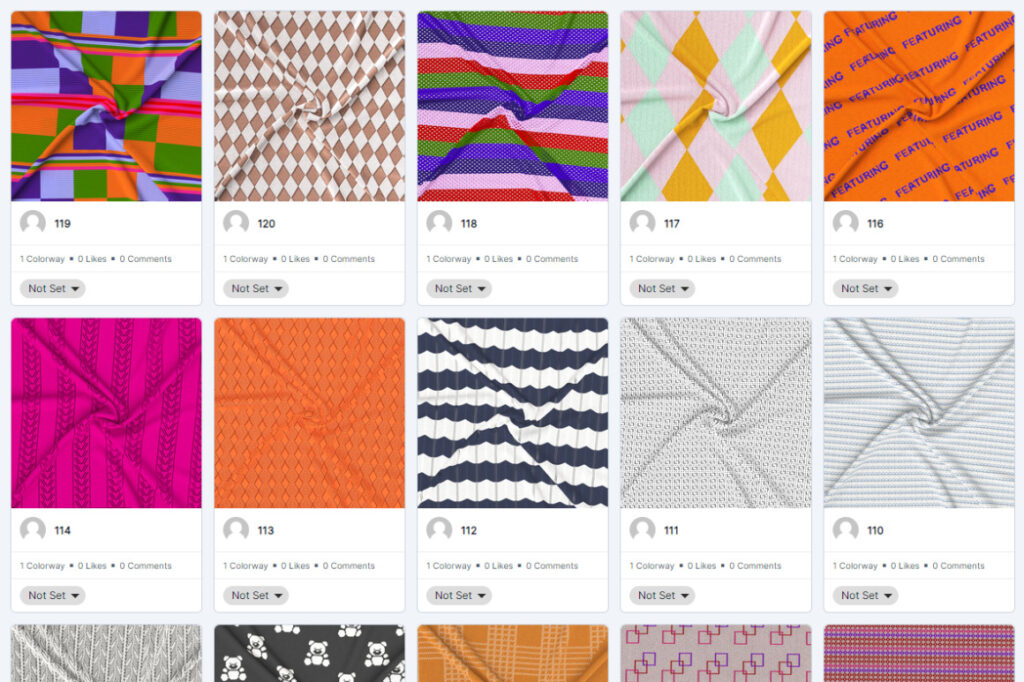

The emergence of 3D technology allows for the accurate virtualisation of fabrics, allowing for the immediate use of the actual fabric in the early stages of the design process., but in the virtual space. This is further enabled by globally accessible digital libraries, which enhance collaboration and provide easy access to virtual fabrics, yarns, stitches, and trims. 3D virtualisation solutions like FAB fabric analyser and xTex Vizoo help to create digital fabric assets that build the foundation for 3D acceleration. By focusing on quality assets from the get-go, designers can simulate accurate styles, visualise fabric behaviours and drapes, and gain a better understanding of fabric properties. At the same time, they can assess the fit and appearance on various body types throughout the development process without doubling the work.

Digital Pattern Development

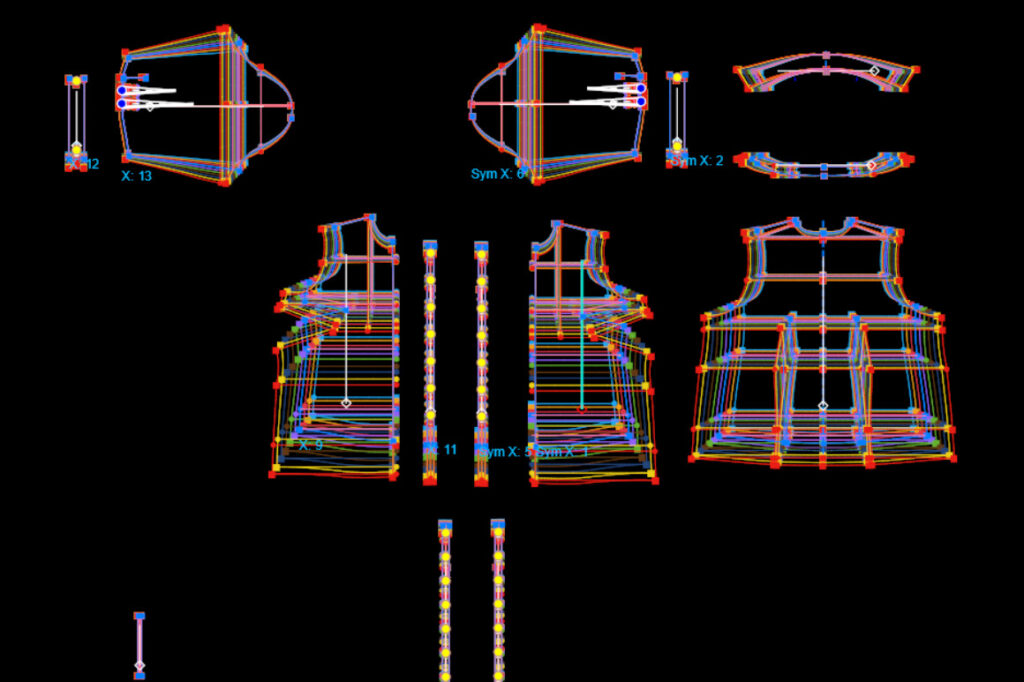

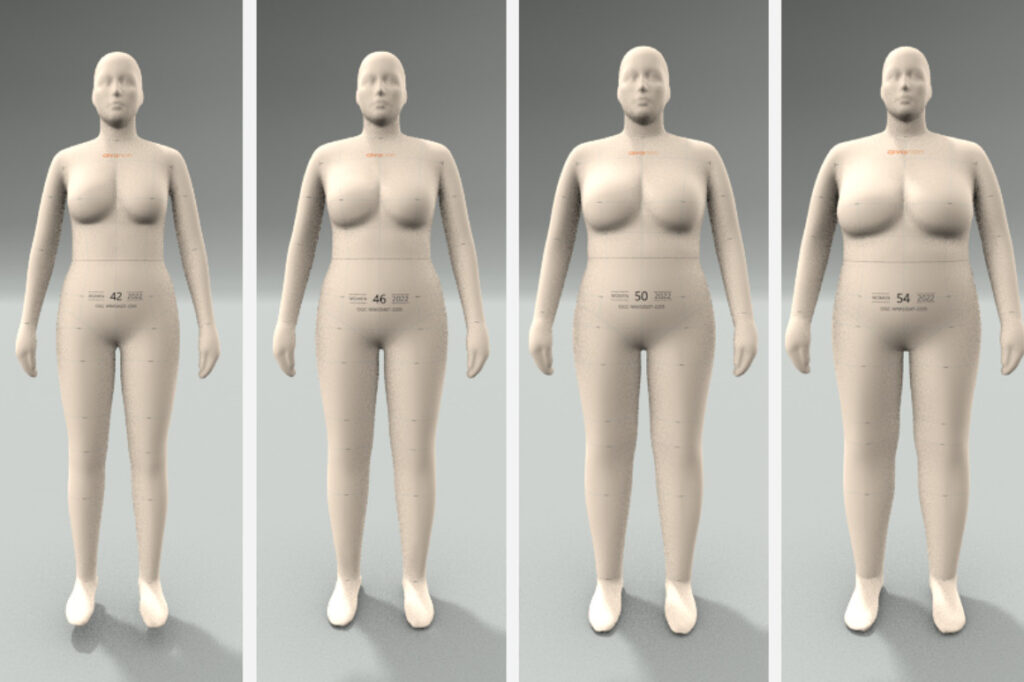

Often, pattern development is a long back-and-forth process between pattern creation in 2D pattern systems and the reviewing of the corresponding physical samples. In many cases, every adjustment of the digital pattern requires a new physical sample to make the pattern and style approval possible. By implementing 3D digital solutions in pattern development and creating globally accessible block patterns, designers can reduce development time, improve fit harmonisation, and produce a better overall product.

Furthermore, our digital pattern solutions and immediate 3D style visualisation streamline the entire development process; it facilitates seamless communication among designers, pattern makers, and manufacturers. As a result, designers can make immediate corrections and adjustments with high measurement precision during try-ons on digital dummies.

Our approach to digital pattern development is a more efficient way to create block patterns and size sets, allowing for standardised dummy sizes for efficient allocation and harmonising with global fit standards.

3D Style Creation

Digital solutions are transforming the traditional product development process. Typically, there are numerous physical samples for each style, such as ones for counters, fittings, pre-production, and photoshoots. These samples are often discarded if designs are dropped or inaccurate and ultimately end up in landfills.

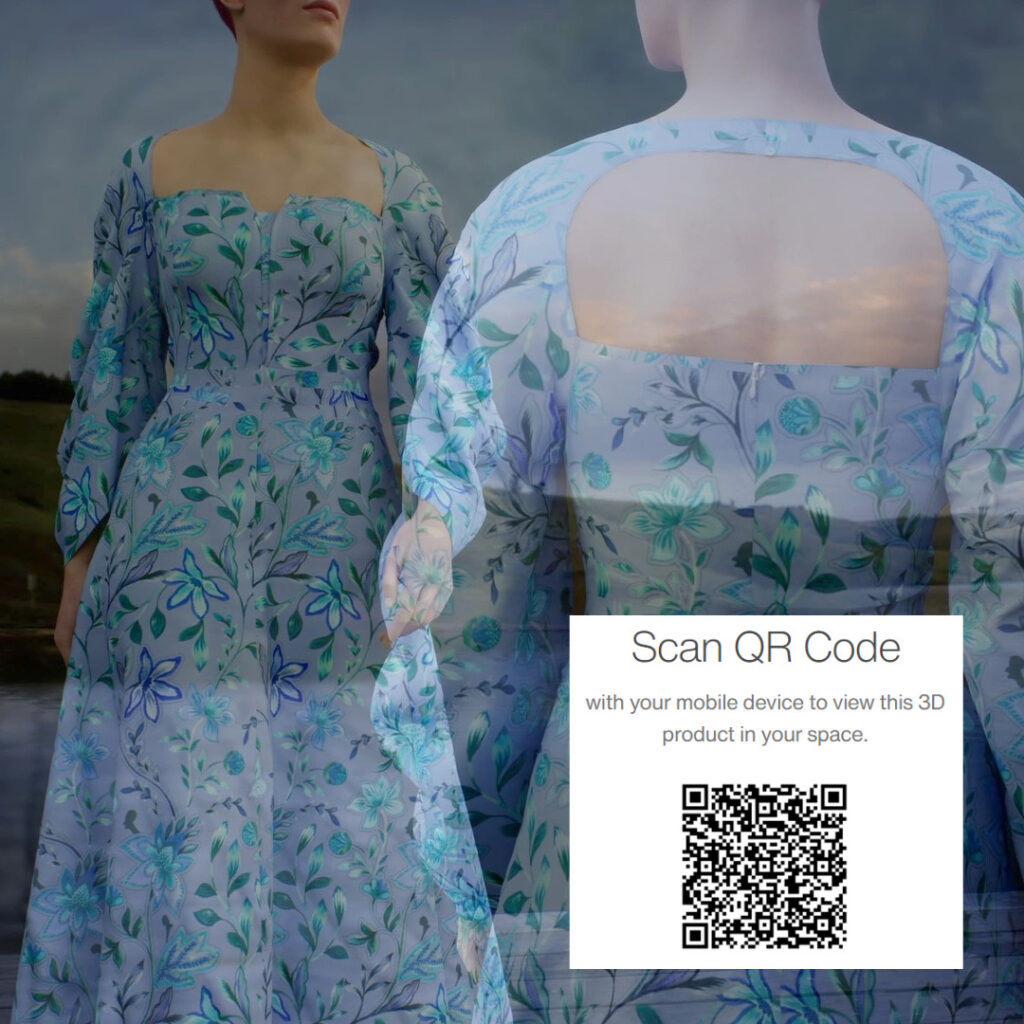

With 3D style development software, like Vstitcher from Browzwear, designers can flexibly create their own 3D designs, add details, and modify fabrics on virtual models. Therefore, enabling the creation of photo-realistic images of completed outfits and digital assessment of fit, materials, trimmings, and silhouette. Virtual alterations can be made without cutting any fabric, meaning no waste is generated.

By generating tech digital packs and digitising all product details and material consumption, manufacturers can also enhance their efficiency by reducing the quantity of physical samples for costing and negotiation with brands. This streamlines the process and directly contributes to sustainability in the fashion industry.

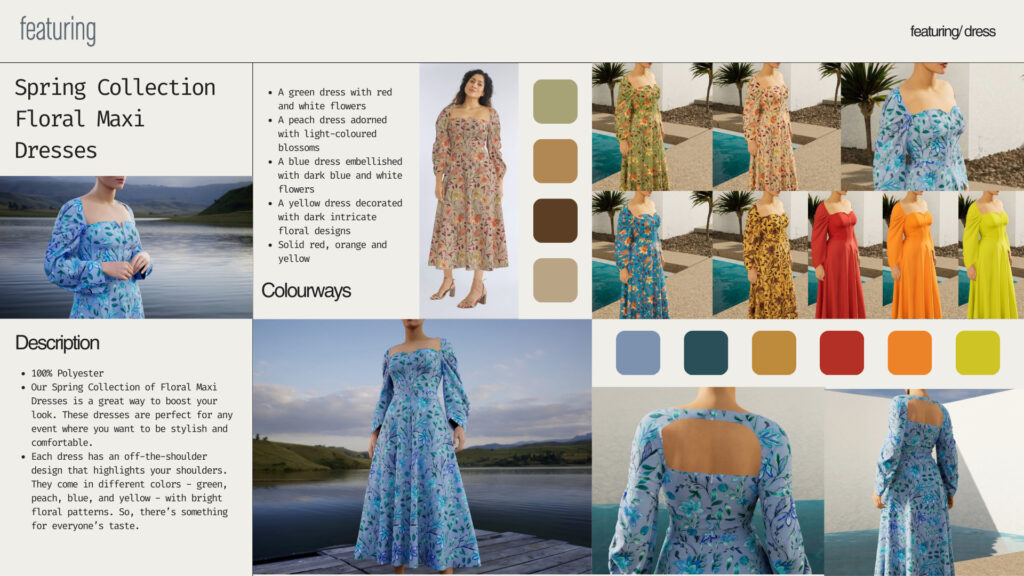

Product Sales and Marketing

3D technology is reshaping the way the fashion industry approaches marketing. Through virtual product displays, there is no longer a need for physical shoots, saving substantial time and resources. By eliminating these costs, companies are able to free up marketing budgets and strategies; the cost per SKU in the current process with physical samples can range from 25 to 150 USD.

Additionally, digital tools and platforms offer real-time interactions and present collections in a dynamic and interactive way. As a result, companies can enhance their customer engagement, provide in-depth product insights, which ultimately reduce the average return rate.

Figure 10: Displaying 3D garments in various ways

The integration of 3D technology into the fashion industry marks a step towards environmental responsibility. Digital interventions create production efficiencies, and enhance the customer experience, meaning the products consumers want can be designed and manufactured with ease. But our four approaches go beyond mitigating the environmental impact of textile production: they set a new standard for industry-wide sustainable practices. By adopting these approaches, we all move towards a greener future.