Recently, we were featured in the PFSK research report “Digitizing the Fashion Industry” alongside our partner Browzwear.

In this report, the PSFK Research team explores the solutions, tools, and technologies supporting the digitization of the fashion industry. To help our members better understand the early stages of transition in this exciting space, PSFK has identified 7 key trends behind the fashion and apparel industry’s pivotal shift.

PSFK is an American media company that follows and reports on trends. It is headquartered in New York, United States. The name PSFK was originally from the mixed up initials of the founding writers, Piers Fawkes and Simon King (Piers Simon Fawkes King).

featuring LIMITED x Browzwear

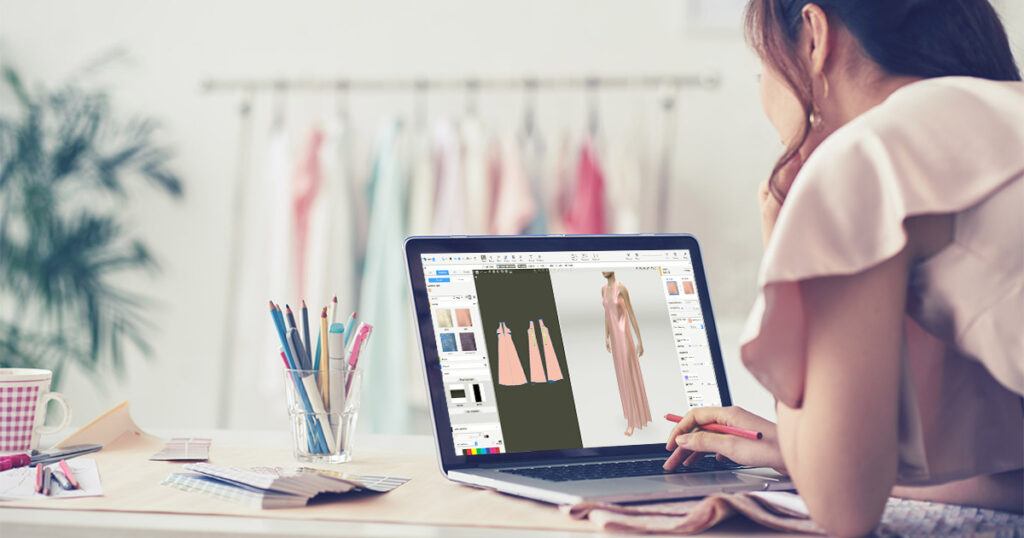

The new training centers from Browzwear, a leading provider of 3D fashion design, development, and merchandising software solutions, will offer digital upskilling to garment design and technical professionals in key manufacturing regions.

Launched in partnership with LIMITED, the product innovation branch of global sourcing leader Otto International, the training facilities will be located in Dongguan, China and Dhaka, Bangladesh; two key strategic and manufacturing-heavy regions. The 3D product development sharing and training centers will provide invaluable upskilling and peer-to-peer sharing, with the Digi-Hubs enabling employees of manufacturers and suppliers, as well as individual designers, pattern-makers, technical designers and others interested in the next generation of fashion production and development, to become proficient in the latest 3D fashion asset technologies by mastering their applications within product design and development.

The companies hope their new 3D fashion design software training centers accelerate the already-nascent, large-scale digital transformation happening within the fashion and apparel industry by using the latest technologies and production procedures to create efficiencies, reduce waste, and increase sustainability. Attendees of the program will gain invaluable experience working with Browzwear’s VStitcher, a widely-used platform for 3D prototyping, as well as acquire skills covering the use of fabric digitization tools like Browzwear’s Fabric Analyzer and Vizoo’s 3D scanning system, that translate the physical properties and textures of textiles into true-to-life virtual samples and 3D simulations and renderings.

With this new knowledge base and toolkit under their belt, Digi-Hub attendees and the apparel companies they work for will be able to seamlessly produce virtual samples that act the same as physical samples and remove productivity barriers, speed up time to market, and enhance sustainability.

This article originally appeared in PSFK’s research paper, Digitizing the Fashion Industry.

featuring LIMITED, the virtual development competence center of Otto International, is an Otto Group company. featuring LIMITED uses the latest in 3D technology to make apparel and footwear product design fast and flexible, providing design and sourcing services in a one-stop-shop.